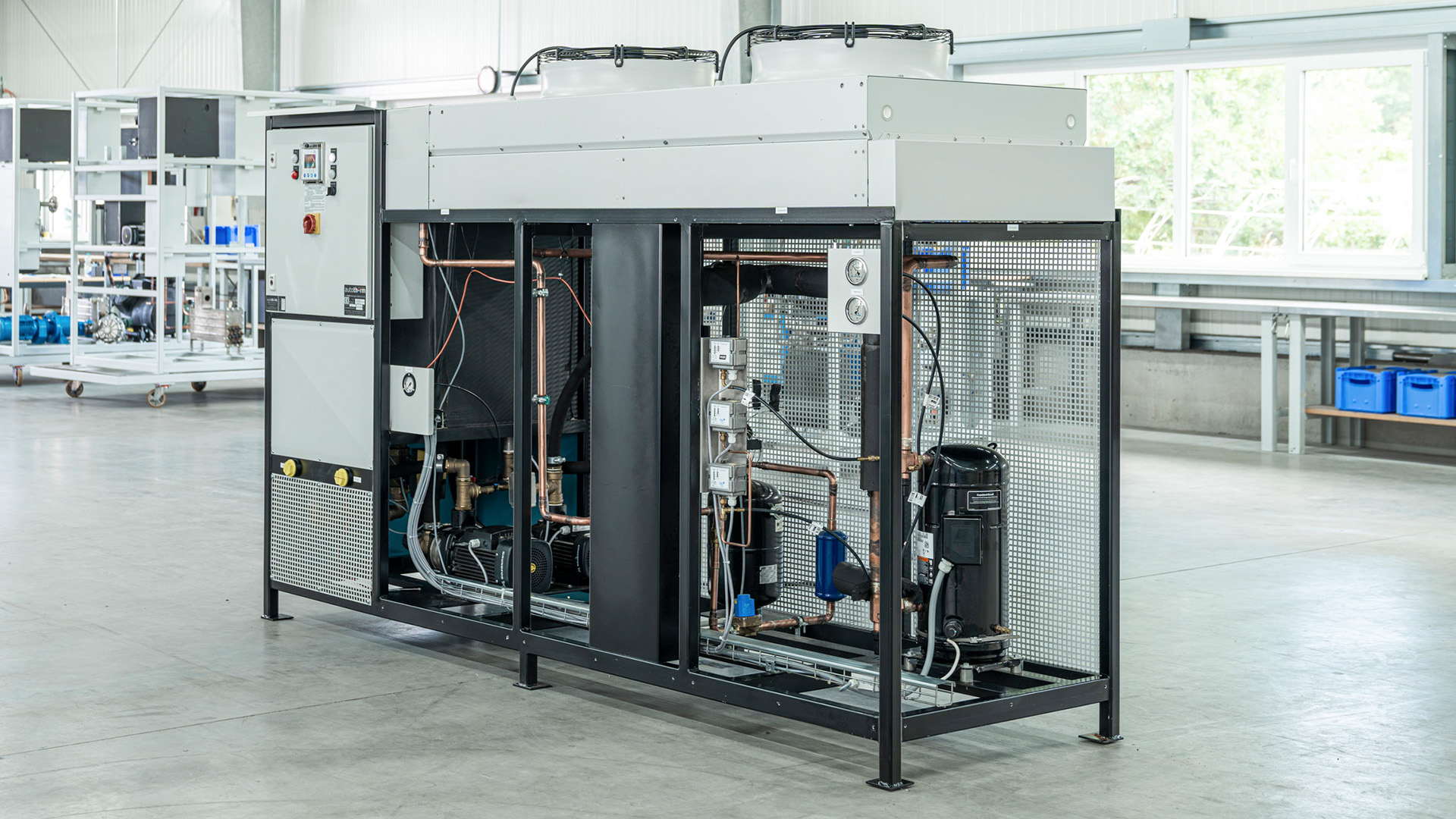

autotherm AKL / AKW recooling systems: Powerful cooling and efficient dissipation of process heat

Working principle

A compression refrigeration system works on the principle of extracting heat from the cooling medium. A refrigerant evaporator absorbs heat from the cooling medium, which is then efficiently transferred to the environment or an external cooling circuit via the refrigerant condenser. Integrated pumps convey the medium from the built-in tank and continuously supply the connected consumers with the required cooling medium.

Areas of application

autotherm recooling units are used in a wide variety of industries and applications:

- Automotive industry

- Metal processing

- Die casting

- Plastics processing

- Paper manufacturing

- Chemical industry

- Food industry

- Lasers

- Pharmaceutical industry

- Test benches

Standard Features

- Installation ready for operation

- IP54 control cabinet with operating and display elements

- Integrated large-volume tank

- Powerful pumps, optionally speed-controlled

- Large-area heat exchangers to increase energy efficiency

- Low-noise fans

Examples of further upgrade options

- Systems for outdoor installation

- Use of natural refrigerants

- Split systems

- Special voltages and frequencies

- Extended temperature range from -50°C to +140°C

- Paint finish in RAL colour as specified at no extra charge

- Various interfaces (analogue, Profinet, Thercad, Modbus TCP/IP CanBus, OPC-UA)

- Remote monitoring modules

- Speed-controlled pumps and compressors to increase control accuracy and energy efficiency

- Extended temperature range down to -50°C

- Cooling of various media such as oils, brines and coolants

- Device geometry adapted to the installation site

- Housing, cladding and control cabinet in stainless steel design

- Media-contacting components made of V2A or V4A stainless steel

Technical data

Our data sheets are available for download as PDF files via the following links.